- ZERO 26 – OVERVIEW

- SALTpro | PRO WAVE from €659

- SPY | FREESTYLEWAVE from €699

- SLASH | FREESTYLE from €599

- RUSH-1 | FREE SL from €689

- AC-0 | NO CAM RACE from €879

- AC-2 | 2 CAM RACE from Feb 026

- AC-3 | 3CAM RACING from €879

- AC-1 LTD | RACING from €1059

- F1 | FOIL RACING from Feb 026

- F0 | FOIL RACE NO CAM from Dic 025

- Q-BOND SAILS DETAILS

- QBOND DARK SERIES

- ZERO 25 – OVERVIEW

- SALTpro | THE WAVE from €649

- SPY | FREESTYLEWAVE from €659

- SLASH | FREESTYLE from €569

- AC-F | CROSSRIDE from €639

- AC-0 | NO CAM RACE from €749

- AC-2 | 2 CAM RACE from €789

- AC-1 | RACE SERIES from €839

- F1sl | FOIL PRO RACE from €999

- F1x | FOIL NO CAM RACE from €799

- SKOOL | EASY LEARNING

- S-LINE | RENTAL SAIL

- BLACK ARCHIVE

OVERVIEW

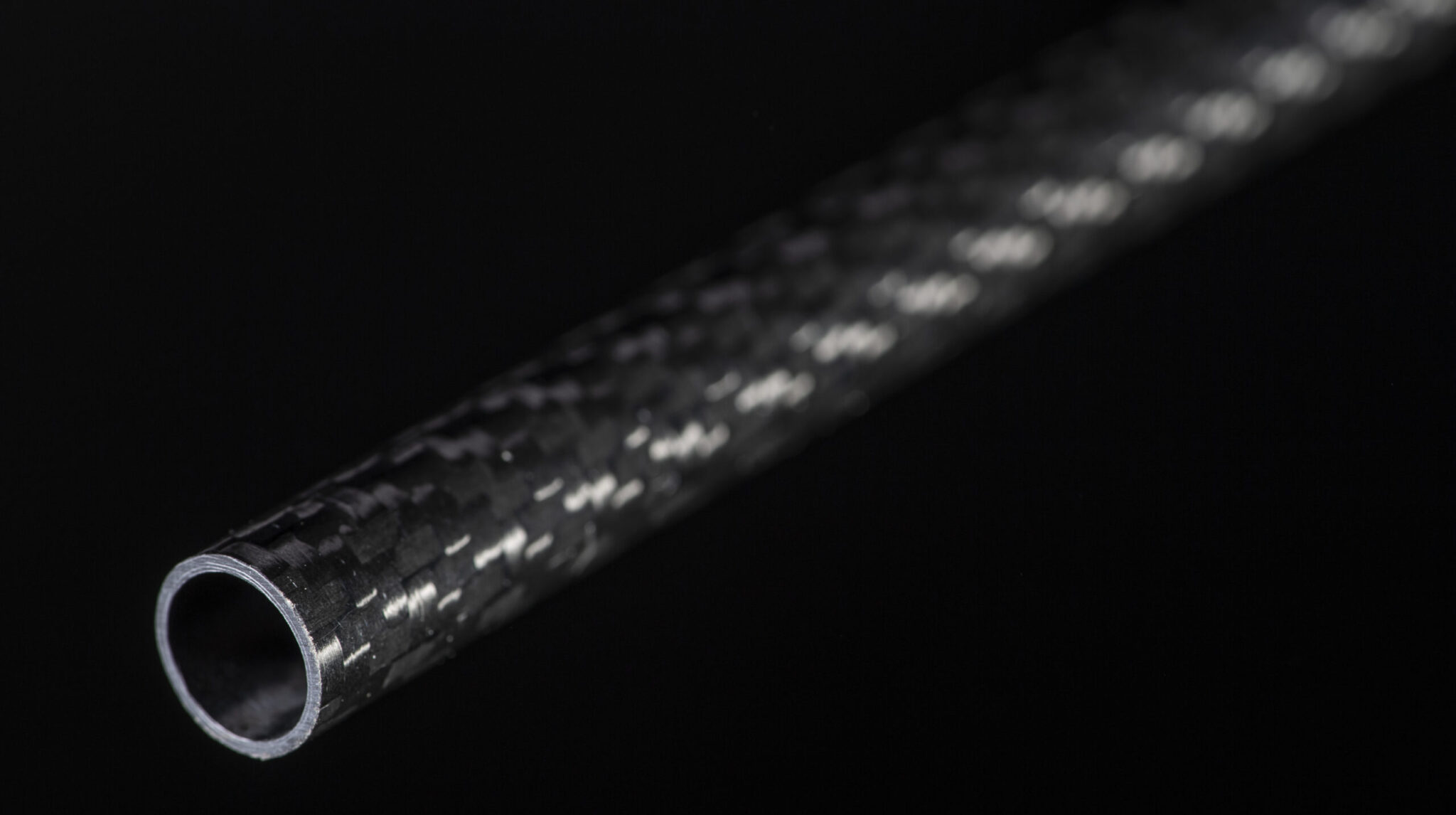

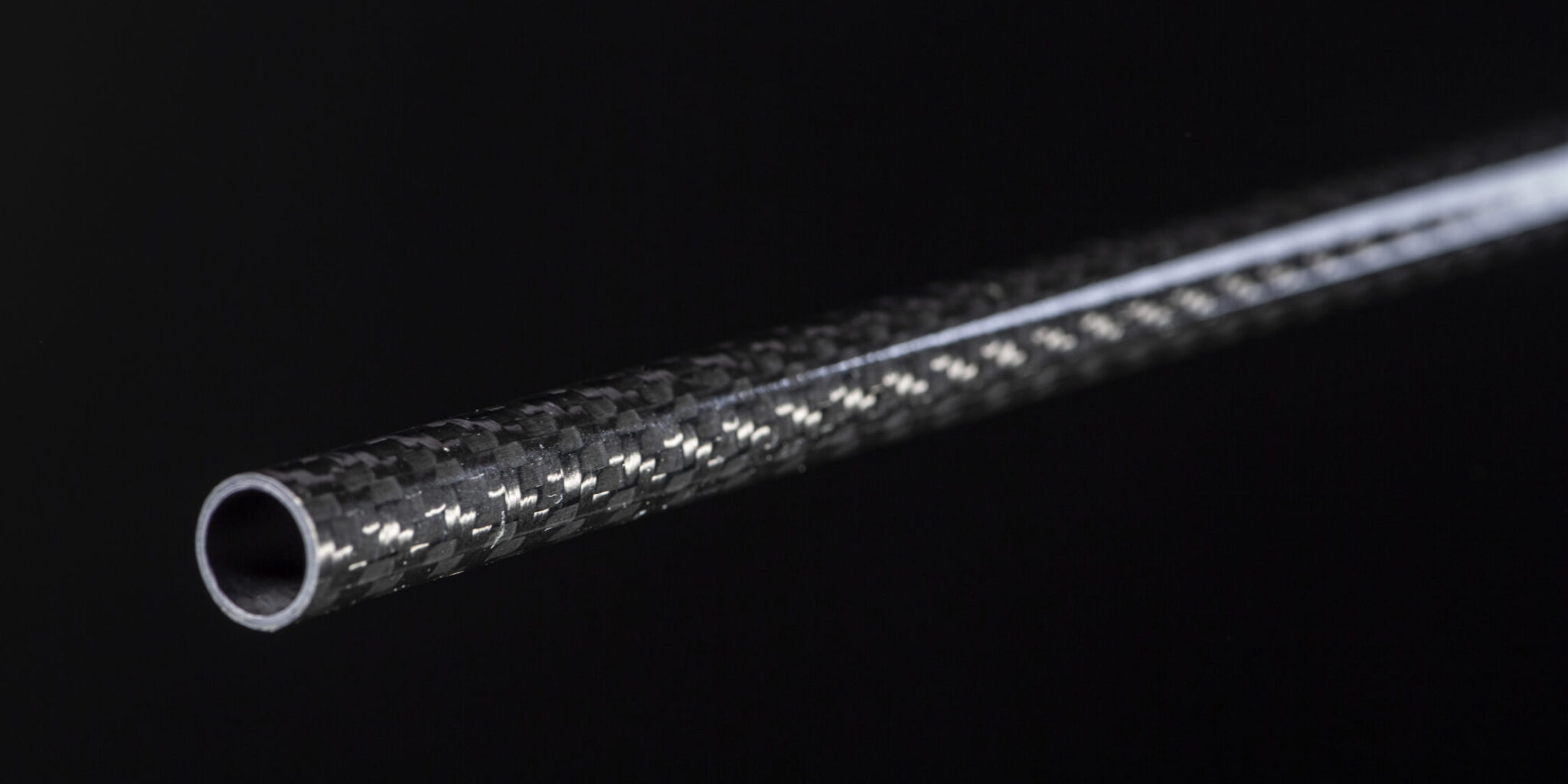

PRO CARBON BATTEN TUBES

MADE IN GERMANY

OFFERING SPECIAL CARBON TUBES TO ENHANCE THE PERFORMANCE OF YOUR RACING SAIL.

There are 2 weights in windsurfing. On land and on the water. It does not mean that a heavier sail on land is going to be heavier than the light sail once on the water sailing. It can be even the other way round, where a heavier sail being efficient in it’s materials reflex, donates a lighter feeling than a sail with lighter materials which might blow up in the wind due to light stretchy materials. Sometimes too stiff carbon material could also bring either too much reflex or too stiff feeling which kills breathing efficiency and comfort to the rig.

WHY THIS BATTEN:

We made sure that the tubes we offer have the same curve and stiffness as our production tubes, giving the following advantages:

Lighter on land.

Increasing the light feel on the water.

Faster natural reactivity to follow the natural flex and reflex of the sail.

Lighter to pump

Better comfort in higher wind range.

WHY NOT ANY CARBON TUBES CAN FIT OUR SAILS?

Often carbon tubes are stiffer than what is needed in our sails by:

Killing the wind range in light wind by not letting the sail breath,

Flattening profiles needed to give power,

Not allowing the s-shape to work as the wind increases, therefore decreasing comfort and speed in stronger winds

MADE IN GERMANY

Very precise, cylindrical, manufactured using prepreg wire-wrap process

Unidirectional fibre with glass scrim weave

Top layer carbon-roving visual structure – canvas

External diameter ground/smooth with diameter tolerance ± 0.1 mm

Surface smooth

Temperature-resistant up to 120°C

Outstanding bending resistance

Layer structure:

80% of fibres unidirectional

20% of fibres canvas top layer

WHICH BATTEN TO REPLACE?

ONLY BATTEN 1 TO 4 COUNTING FROM THE TOP OF THE SAILS ARE THOSE TO BE REPLACED. LOWER 3 BATTENS WILL REMAIN THE PRODUCTION ONES.

IN THE PACK. INSTRUCTION TO REPLACE THE ORIGINAL BATTENS:

| Batten positon | Type | Pro Carbon Tube | Action | Batten Tensioner |

|---|---|---|---|---|

| (Top Batten) 1 | 1 piece batten | 8-10mm | Cut to same size as original | Use original |

| 2 | 1 piece batten | 8-10mm | Cut to same size as original | Use original |

| 3 | 2 piece batten | 10-12mm | Take out batten tip from tube. Grind 2mm the plastic ferrule to insert into the 10-12 pro carbon tube after having cut it to size. | Use small tensioner sent with new tubes battens |

| 4 | 2 piece batten | 10-12mm | Take out batten tip from tube. Grind 2mm the plastic ferrule to insert into the 10-12 pro carbon tube after having cut it to size. | Use small tensioner sent with new tubes battens |

| 5 | Original | |||

| 6 | Original | |||

| (Bottom Batten) 7 | Original | |||