MAST OVERVIEW

“The Uncompromising Excellence of Italian-Made Windsurfing Masts”

When it comes to windsurfing masts, quality is non-negotiable. High-performance masts aren’t just built—they’re engineered with precision, and the best in the world come from Italy. Despite the global presence of various companies, Italy remains the heart of top-tier mast production. But here’s the key difference: while some so-called “Italian” companies might operate from abroad, our supplier is fully based and manufactures in Italy—a crucial distinction.

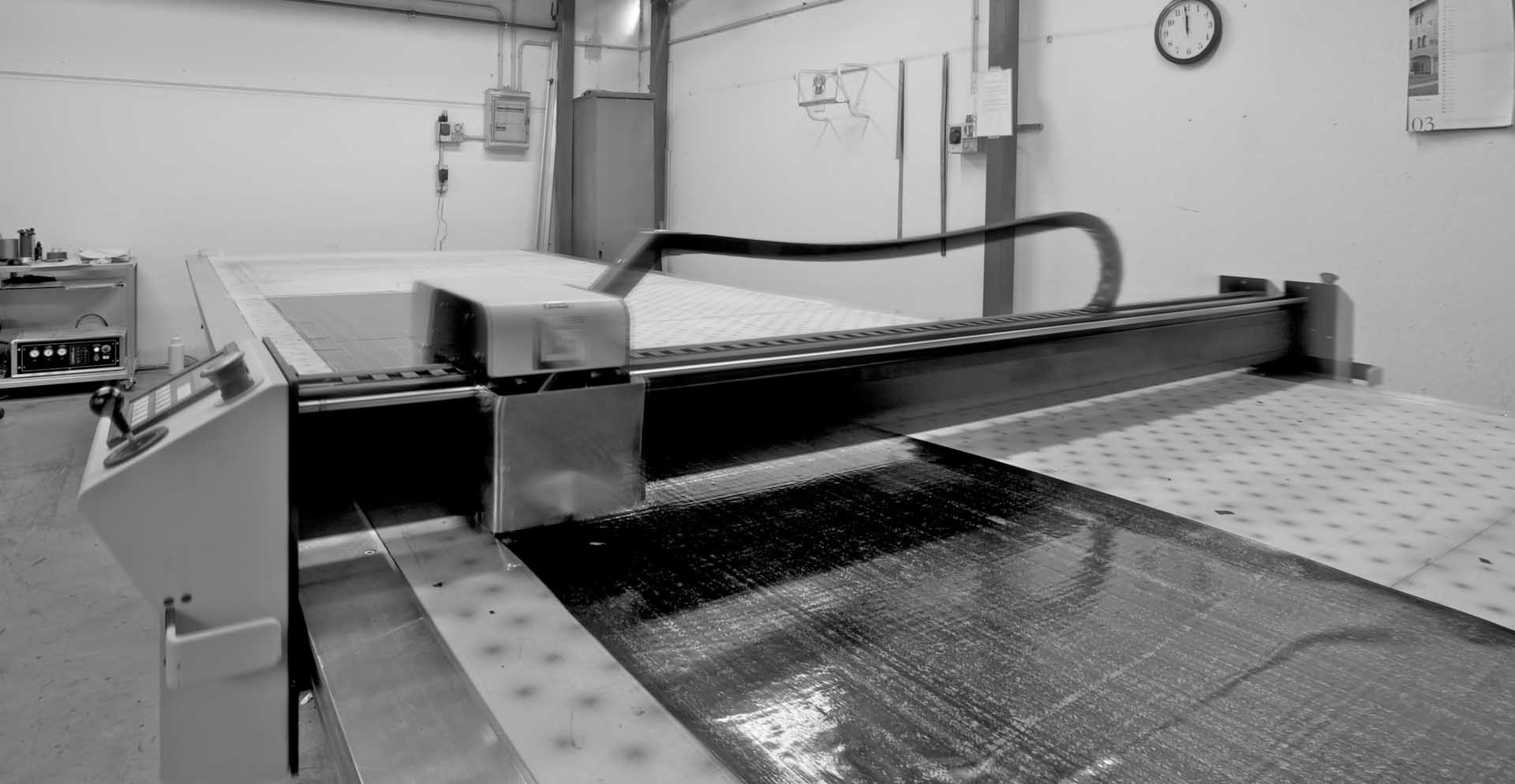

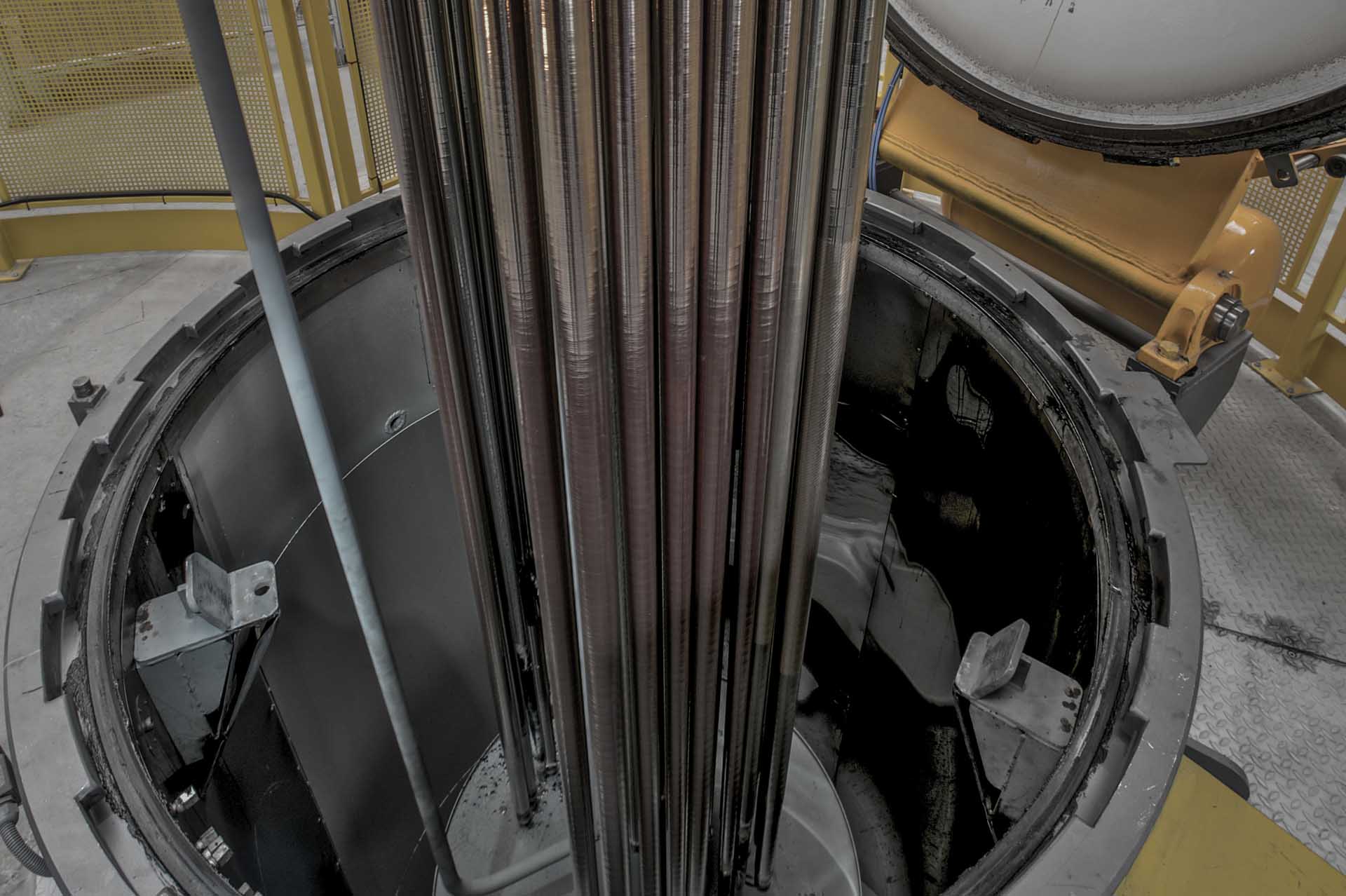

We work with the only factory that produces its own carbon pre-peg, ensuring unparalleled control over the entire production process. Yes, many masts might appear the same, but the truth is, they’re often made by different manufacturers with varying machinery, materials, and technologies. That’s why quality can’t always be guaranteed.

At Point-7, based in Italy, our supplier based in Italy, we don’t just follow standards—we define them. Our production process is built for continuous innovation, ensuring that every mast leaving the factory meets the highest standards. This commitment to craftsmanship means that the materials we use exceed the requirements for durability, performance, and reliability.

We’re also proud to say that our factory is the only one producing its own carbon pre-preg. This gives us the huge advantage of using fresh, high-quality material in every production run—no storing, no freezing, and no compromise. Unlike other manufacturers who purchase pre-preg material from third parties and store it in and out of freezers, we ensure that every batch of material is freshly made for each production cycle, guaranteeing superior quality from start to finish.

CHOOSE YOUR MAST 2025

SDM-S 025

329,00€ – 669,00€K SDM-S SERIES: THE SONIC EDGE FOR MAXIMUM CONTROL AND STABILITY

We’ve added the ‘S’ for Sonic to our SDM masts, introducing a new construction at the top of the mast that enhances reflex in the winglet area of the sail. This innovation significantly improves control and stability, giving you a sharper, more responsive ride on the water.

The K SDM-S masts are available in three carbon percentage gradients: K100, K93, and K77, each designed to offer different levels of performance and durability based on your needs. These masts are built to cover a range of conditions and sailing styles, ensuring you get maximum performance no matter your setup.

Sizes

K100 | 100% Carbon | 430 460 490

K93 | 93% Carbon | 430 460 490

K77| 77% Carbon | 430 460

RDM-i 025

309,00€ – 589,00€RDM-I: Reduce Diameter- Inverted.

Made in Italy.

Once you take your Point-7 mast out of its mast bag, don’t think for a second that something’s wrong. The ferrule is now part of the top, not the bottom. We’ve re-engineered this for maximum performance and durability, and the mast is now referred to as RDM-I. After extensive testing with our wave team, we discovered that hard landings, flat crashes, or nosedive jumps were creating excess stress on the top, specifically where the ferrule would enter. By moving the ferrule to the top, we’ve removed that stress, preventing potential damage to the top section and reducing the risk of breakages during extreme maneuvers.

We are proud to introduce three distinctive models in our lineup: the K71, K91, and K99—each with increased carbon content compared to the older models.

Available sizes:

K99 | Carbon 99% | 300, 340, 370, 400, 430

K91 | Carbon 91% | 340, 370, 400, 430

K71 | Carbon 71% | 340, 370, 400, 430

F100 designed for foil sails

629,00€ – 749,00€BUY A 2024 F1SL, use code F1slF100 and get 20% off the mast.

COMMITED TO FLY.

At Point-7, we don’t deal in compromises. If you want the absolute best performance from your foil sails, you need dedicated foil masts. We’ve developed a line of masts designed specifically to enhance the performance of Point-7 foil sails—not some generic solution that does a disservice to your ride.

We understand foil sailing is a completely different game compared to traditional fin sailing. That’s why our masts are engineered to push the limits, giving you maximum control, efficiency, and speed in every condition.

For those who demand unmatched precision and zero compromises in their performance, Point-7 foil masts are the only choice. Anything less? It’s just a waste of your time.

Sizes

F100 | 100% Carbon | 460 490 520 570