What Defines the Perfect Sail? WIND RANGE.

When it comes to sail development, everything boils down to one essential characteristic: WIND RANGE. This is the key to maximizing your time on the water, ensuring that a single sail remains efficient even when the wind drops or picks up beyond what you initially expected.

So, what creates WIND RANGE? Two critical factors: Power and Stability. Power delivers performance across varying conditions, while stability ensures you can harness and control that power seamlessly over a broader wind spectrum.

But what influences these factors? While design is the foundation, material selection plays an equally crucial role. A common mistake is using materials that are too light, especially in the upper body panels (above the boom), compromising durability and performance. Some brands chase weight reduction on paper or in the shop display, but sacrificing structural integrity leads to reduced wind range. Lighter materials can deform, lose efficiency, and become unstable, ultimately making the sail feel heavier and harder to handle on the water.

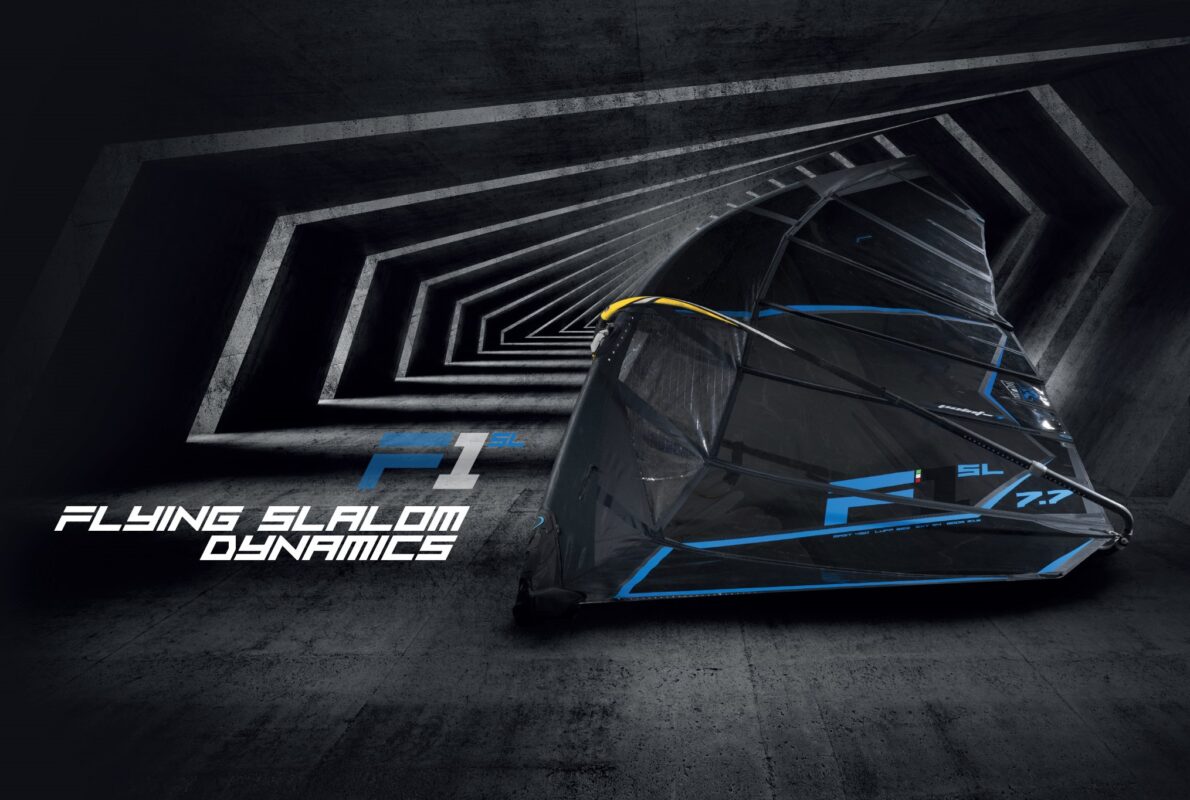

Ever noticed how new windsurfing sails appear in magazines as sleek, futuristic designs before they even exist in real life? Just like concept cars, the first glimpses of new sails are often nothing more than digital renderings. Yet, from the moment these images hit the internet, beach talk spreads like wildfire:

“Have you seen the new sail? It looks more powerful! The boom seems longer… I heard it’s super light!”

There’s something special about unrolling a brand-new sail on the beach for the first time. Everyone gathers around, commenting on reinforcements, color schemes, and potential performance benefits. But the truth is, until that sail touches the water, no one really knows how it will perform. Even the team and designer make changes knowing what these will bring, but the water is going to reveal the truth.

What most don’t see is the relentless testing, the countless prototypes, and the continuous refinements that take place long before that sail makes its way into a windsurfer’s hands. So how does a sail evolve from a designer’s sketch to the finished product that fuels our windsurfing passion?

At Point-7, every sail begins with one key factor: windsurfer. Development starts with feedback from customers, team riders, and testers. That’s why each discipline has multiple sail lines, offering different styles for different skill levels, power preferences, and wind conditions. Alongside routine refinements, we also push long-term projects—true innovations that bring fresh challenges and progression to the sport.

The development cycle never stops. The only limitation is the production deadline. The moment a sail goes into production, we’re already deep into testing and designing the next version. While consumers are receiving their latest models, our test team is finalizing the sails for the following season.

The timeline varies depending on the sail type

- Race sails: Testing peaks in late summer after receiving feedback from PWA riders. With the registration deadline in December, the final production model must be locked in by mid-December.

- Wave sails: The windiest testing period runs from November through April, ensuring they handle everything nature throws at them.

- Freeride & Free race sails: Developed from winter through May, taking advantage of varying conditions for a well-rounded testing process and in summer given to friends and random riders to have final feedback.

A critical part of the development cycle is stepping away from a sail line for a while. When you return to it with fresh eyes, you instantly feel what needs changing—or what doesn’t. Having all our tested to jump on different sail lines is one other important step. You can learn from a wave sail, details that can be used on flatwater sails and vice versa.

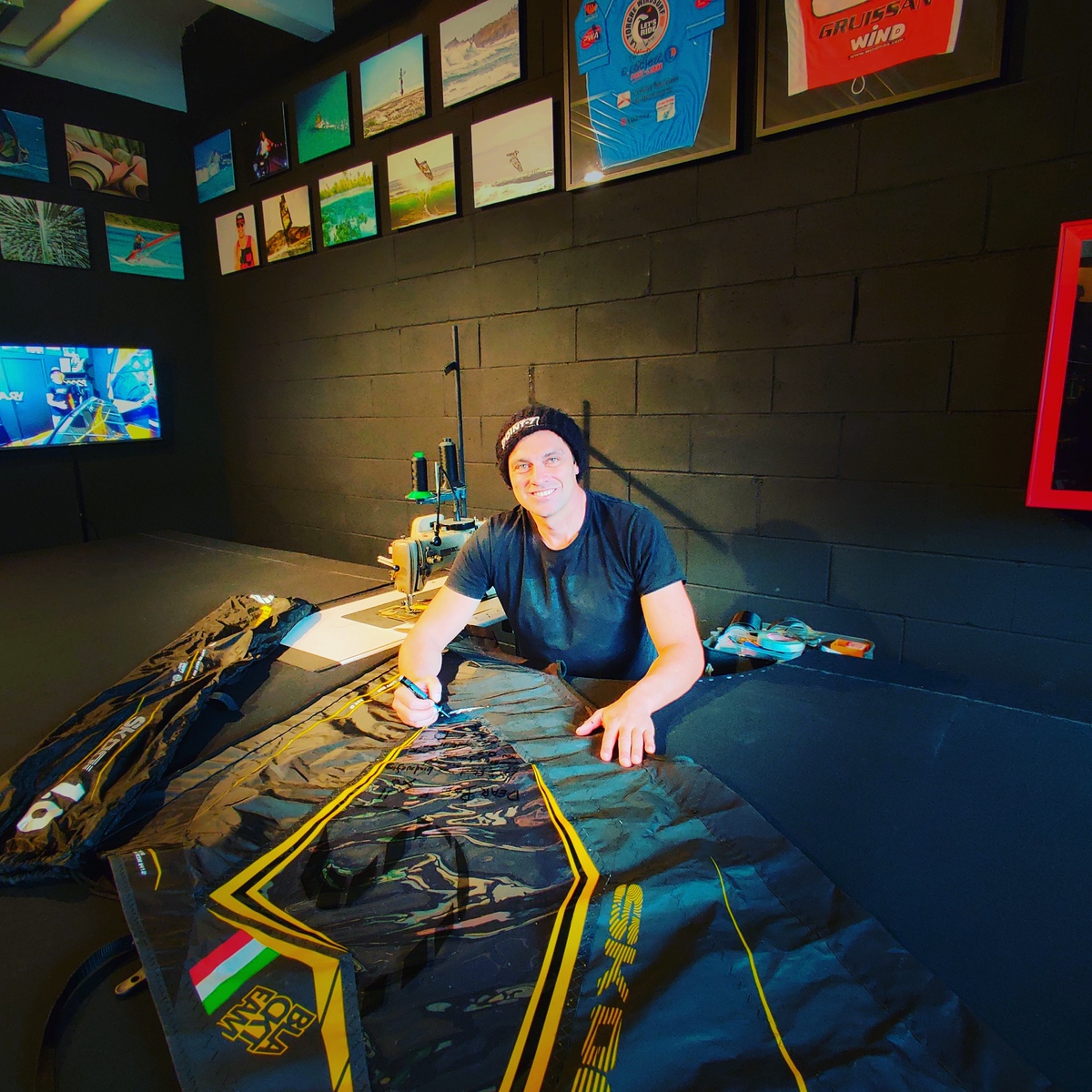

The first step in a new sail’s journey is an intense meeting between the sail designer, marketing director, test riders, and customer feedback analysts. It’s a brainstorming session filled with discussions on performance tweaks, size additions, boom lengths, materials, colors, mast compatibility, and more. The sail designer then takes all these inputs and starts crafting the first prototype files.

Even choosing a name can be a challenge. Often, it isn’t until a sail is seen in action on the water that its identity reveals itself.

Precision in Mast Design: The Secret to Ultimate Rig Efficiency

The next critical step in sail development is determining mast compatibility, a fundamental factor in maximizing rig efficiency. At Point-7, we continuously refine our masts with the latest technology and tooling, but one principle remains unchanged: the mast curve must complement the conditions each sail size is designed for.

Here’s the key

- Longer masts are designed to be more powerful and responsive, breathing with the wind to generate drive and acceleration.

- Shorter masts prioritize control and forgiveness, ensuring a balanced and effortless ride even in gusty conditions.

This tailored approach expands the wind range before even touching the sail design. And because we’ve perfected these mast curves, we don’t change them, we evolve the sail around them. That’s why every Point-7 mast from 2011 onward remains fully compatible with every Point-7 sail from 2011 onward.

And if you try our masts on any other sail brand? Be ready to be surprised.

Crafting the Perfect Balance: Materials, Aesthetics & Performance

Once the sail’s shape is perfected, the graphic designer steps more than just adding colors and branding, this stage is about engineering a sail that is both visually striking and structurally bulletproof. Every material is meticulously selected to balance lightweight performance, UV resistance, and long-term durability.

At Point-7, we source only premium materials from Japan and the U.S. Colored monofilm, for example, costs up to five times more than its transparent counterpart—but the payoff is worth it: superior UV protection and extended lifespan.

But here’s the hard truth: even the best sail design can fail if the materials aren’t up to standard. If a sail uses less than 4-mil thick materials, no matter how much X-ply reinforcement is added, stretching will ruin its wind range. A lightweight sail might look good on paper, but if it deforms under pressure, it loses stability, control, and ultimately—performance.

That’s why at Point-7, we don’t chase gimmicks.

Once the digital design is finalized, the prototype is cut and built. Some brands do this in-house, but we choose to have our prototypes made by the same manufacturers who handle our final production sails—ensuring consistency and quality control.

From file submission to receiving the prototype, it takes about two weeks. In this time, over 30 prototypes can be cut and assembled, a process that would take months if done manually.

When the sails arrive, the excitement is electric. Boxes are opened like Christmas gifts, and for a moment, everything goes silent as designers, testers, and riders examine the results of months of hard work.

But before hitting the water, each sail is rigorously checked. Mast and boom lengths are verified, and graphic elements are compared to digital renderings. If something is off and can be seen directly after rigging, it’s modified straight away. Then, finally, it’s time to rig up and ride.

Real Testing, Real Conditions

At Point-7, we don’t test in a lab—we test where it matters: on the water, in real conditions, pushing our sails to the limit. Our Lake Garda test center is the ultimate playground for tuning and refining every detail of our designs.

The Perfect Testing Ground

Our sail loft, just 2km from the beach, allows us to make instant modifications—we’re talking for 5 minutes for minor tweaks and 30 minutes to be back on the water after stitching adjustments on the sail. The side shore wind, combined with a car park just 10 meters from the water, means we can fine-tune performance without dealing with salt, sand, or delays.

From Extreme to Subtle Conditions—All in One Day

Testing at Lake Garda is an all-day wetsuit mission. Mornings kick off with 30+ knots of wind, gradually easing throughout the day—the perfect setup to test multiple sail sizes in one session. And just when you think we’re done, the afternoon winds kick in at 22-25 knots, allowing us to fine-tune the sails twice a day, every day.

This is real testing

The Golden Rules of Testing

Developing a new sail isn’t about hype—it’s about precision, patience, and pure performance. Every sail must pass through a rigorous testing process before even being compared to its predecessor.

Step 1: The Sail Must Settle

A brand-new sail doesn’t reveal its true character right away. It needs a full day of stretching on the water to settle on the mast, allowing the materials to adjust before fine-tuning begins.

Step 2: Eliminating Variables

A true test isn’t just about speed or pulling off a big move—it’s about raw data and unbiased comparisons. Every mast is measured, documented, and swapped between sails to ensure the results aren’t skewed by variations in flex or curve.

Step 3: Testing with Precision, Not Emotion

Testing isn’t about proving the new sail is better at all costs—it’s about understanding its characteristics. Windsurfing performance isn’t just speed. It’s also:

Acceleration

Comfort

Wind range

Upwind & downwind performance

Jibe entry & exit

For freestyle, sails must make moves effortless, but also plane fast, stay easy in strong wind, go upwind efficiently, and remain stable. Every discipline has its demands, and we dissect every detail.

Step 4: Pure, Unbiased Feedback

After just a few hundred meters, the differences between the new and old sail become clear. Trim adjustments are made, masts are swapped, and every factor is isolated to ensure honest results. Testers do not discuss impressions on the beach—each logs their feedback independently to avoid influencing others.

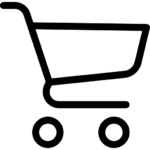

At Point-7, Andrea Cucchi personally gets on the water to feel the changes first-hand. This direct connection between designer and testers is an invaluable advantage, allowing real-time communication and a deeper understanding of every modification. Testers provide feedback one-on-one, ensuring raw, unfiltered opinions. And yes, even a bad night’s sleep is considered—it all matters.

Step 5: Extreme Condition Trials

Once fine-tuned, sails are put through brutal real-world testing:

Racing sails are tested in waves.

Wave sails are tested on flatwater.

This ensures each sail is not only exceptional in its category but also versatile across different conditions.

The Importance of Home Waters

Testing at home waters allows for instant feedback and faster refinement. A spot with chops and gusty winds is ideal for sails, as it quickly reveals strengths and weaknesses. Boards, however, demand varied water conditions, making their testing process more complex.

No shortcuts. No marketing gimmicks. Just relentless testing to deliver the most refined, high-performance sails in the world.

If significant changes are needed, new prototypes are ordered, refined, and retested until the sails meet our exacting standards. Only then do they move into final production.

Before mass production begins, our team makes multiple trips to the manufacturing facility—quality control is non-negotiable. We collaborate with production teams to refine techniques, implement innovations, and guarantee that what customers receive is exactly what we envision.

Some sails undergo over a year of testing, traveling to different team riders worldwide to experience every condition imaginable. They are battered, pushed to the limit, and examined for durability, performance, and innovation.

The biggest challenge? Deadlines. Marketing materials, pricing, and dealer schedules all demand finalization, often before we’d ideally stop testing. But at Point-7, if a sail isn’t 100% tested and approved, it doesn’t go into production—no exceptions and no sails size or model goes in without being tested, even the freeride.

This endless cycle of refinement is what keeps windsurfing exciting. It ensures that every new sail released isn’t just another model—it’s a product of passion, precision, and pure performance.

So, the next time you unroll a fresh Point-7 sail on the beach, know that it has already been through countless hands, countless waves, and countless hours of development to deliver you the ultimate windsurfing experience.